Dissolved Air Flotation (DAF)

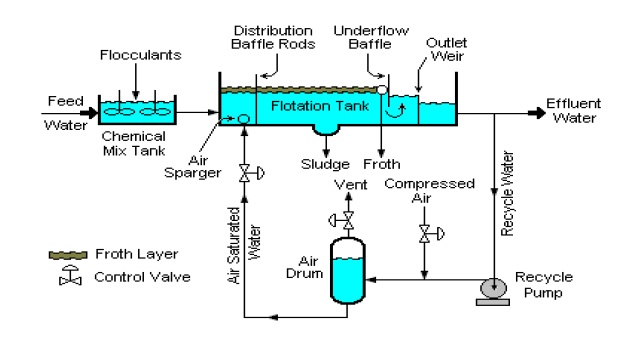

technology is the process where suspended solids, oils & greases, and other impurities are separated from water slurries by a process of dissolving air into water. Micro-bubbles interact with the particles to cause them to float to the surface of a vessel where they are skimmed and separated. DAF system can achieve removal efficiencies and effluent qualities far superior to traditional DAF systems.

To dissolve air for flotation, three types of pressurized systems are used. Full-flow or total pressurization is used when the wastewater contains large amounts of oily material. The intense mixing occurring in the pressurization system does not affect the treatment results. Partial-flow pressurization is used where moderate to low concentrations of oily material is present. Again, intense mixing by passage through the pressurization systems does not affect treatment efficiency significantly. The recycle-flow pressurization system is for treatment of solids or oily materials that would degrade by the intense mixing in the other pressurization systems. This approach is used following chemical treatment of oil emulsions, or for clarification and thickening of flocculent suspensions.

FIELDS OF APPLICATION

Benefits

- Effectively dewaters the oil, making oil recovery much simpler.

- Long life and corrosion resistance.

- Eliminates bridging and plugging of viscous materials.

Applications

- Reduce waste treatment load

- Recover free oil

- Improve process treatment

- Refinery wastewater

- Storm runoff water

- Bilge water

- Desalter waste

- Ballast water

- Reduce slop oil water