The API separator is normally the first, and most important, wastewater treatment step in petroleum refineries. The primary function of a properly designed API separator is to remove the majority of oil and suspended solids from refinery wastewater prior to subsequent downstream wastewater treatment processes. For years, refineries have attempted to use other technologies or treatment scenarios as an alternative to the API separator. But most refineries ultimately select, or return to, the API separator as the technology of choice for their wastewater treatment primary oil/solids separation step. (Note: API stands for American Petroleum Institute.) Before we look at the design and performance aspects of an API separator we’ll talk about oil.

A refinery wastewater may contain oil in three forms and all three forms may be present in a given waste stream. The three forms of oil encountered in wastewater are:

- Free oil

- Emulsified oil

- Dissolved oil

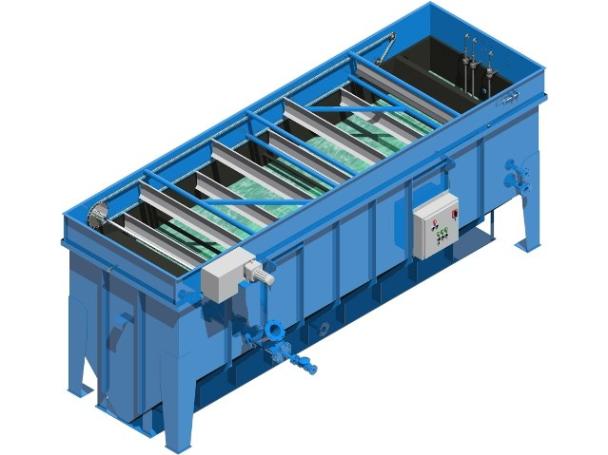

Discrete oil globules will rise due to buoyant forces to form an oil layer on top of the water. This makes them relatively easy to remove in an API separator or they can be skimmed from the surface in an Equalization tank. Free oil can be removed by gravity separation which is what the API separator is designed for. Removal is a function of flow conditions, differences in specific gravity, temperature, and the stability of the oil. Coarse oily solids with a specific gravity >1.0 will settle to the bottom of the separator which is why bottom scrapers or flights are included in along with a conical hopper to collect the settled solids.

Emulsified oil is comprised of oil droplets with a diameter of less than 20 microns, mostly in the 1–10 micron range. Emulsified oil is a stable suspension in the water due to inter- particle forces dominating buoyant forces. Emulsified oil will not separate from the water under quiescent conditions aided by gravity, the very conditions created in an API separator. The removal of emulsified oil requires chemical addition such a pH adjustment to drop the pH or emulsion breakers. Once treated in this way the wastewater often enters a dissolved air (or nitrogen) flotation unit to remove the emulsified oil as it begins to break from the wastewater.

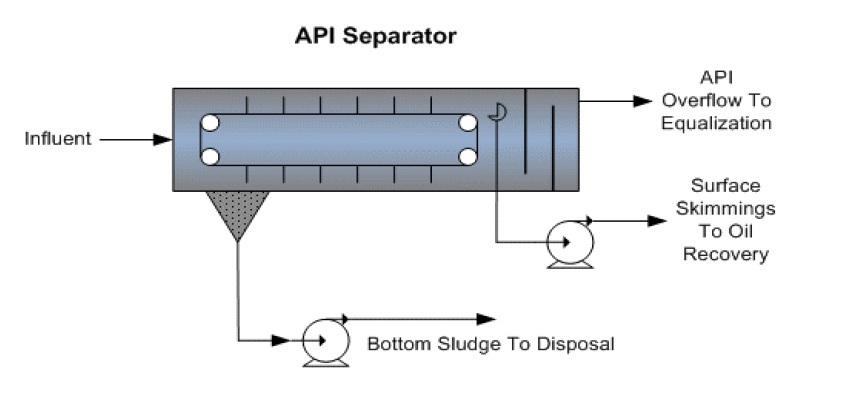

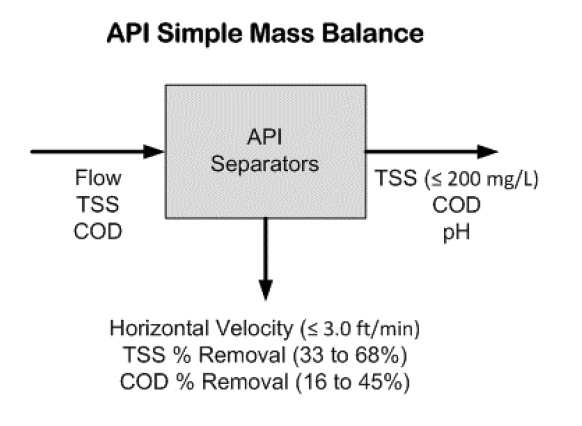

Dissolved oil forms a true molecular solution with water and cannot be removed by gravity separation. Dissolved oil removal requires biological treatment. The API separator, shown in the graphic below left, has become the generic name for “conventional oil-water separators.” Conventional oil-water separators can only remove free oil. Stable emulsions and dissolved oil require additional treatment. A simple mass balance around the API separator is shown in the graphic below right.

Benefits

- Effectively dewaters the oil, making oil recovery much simpler.

- Long life and corrosion resistance.

- Eliminates bridging and plugging of viscous materials.

Applications

- Reduce waste treatment load

- Recover free oil

- Improve process treatment

- Refinery wastewater

- Storm runoff water

- Bilge water

- Desalter waste

- Ballast water

- Reduce slop oil water